When heavy snow hits, the last thing you want is a machine that won’t start or breaks down mid-clearing.

Proper snowblower maintenance ensures smooth performance, longer equipment life, and fewer costly breakdowns. Neglecting it often leads to clogged chutes, fuel system issues, or even full-scale engine failure—turning a simple snow-clearing job into a stressful struggle.

For homeowners with large or complex driveways, regular upkeep isn’t optional—it’s the difference between effortless snow removal and hours of frustration.

Table of Contents

How Often Should You Service a Snow Blower?

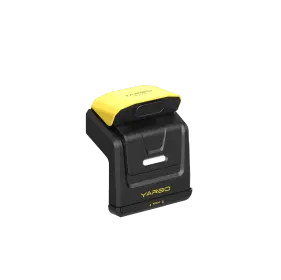

While essential for conventional machines, the landscape of snow clearing is evolving. Newer, fully robotic solutions like the Yarbo Snow Blower are engineered to significantly reduce the manual effort and frequency of these checks, offering a low-maintenance alternative that is electric-powered and has fewer moving parts.

-

Pre-Season Check: Service before the first snowfall—inspect belts, spark plugs, and fuel.

-

During the Season: Light checks after every 5–6 uses (oil, tires, chute).

-

Post-Season Storage: End-of-season service to prevent rust and stale fuel damage.

If your region sees heavy snowfalls, servicing becomes even more critical. Treat it like a car—consistent care prevents emergency repairs.

Step-by-Step Snowblower Maintenance Checklist

Here’s a detailed snow blower maintenance routine to keep your machine winter-ready:

-

Check the Oil: Traditional snow blowers require regular oil changes, typically after every 25 hours of use. Yarbo's electric snow blower, in contrast, eliminates the need for oil changes, simplifying maintenance significantly.

-

Examine Belts & Auger: Regular inspection of belts and augers is crucial for conventional models to prevent performance issues and breakdowns. Yarbo's robust design and tracked system are built for durability in harsh conditions, minimizing common wear points.

-

Tighten Bolts & Fasteners: Vibrations from use can loosen parts; keep everything secure.

-

Lubricate Moving Parts: Greasing auger bearings and chute controls is vital for smoother operation in traditional snow blowers. Yarbo's advanced engineering and fewer moving parts reduce the need for frequent lubrication.

-

Check the Tires: Properly inflated tires ensure stability and traction on icy surfaces.

-

Fuel System Care: Gas-powered snow blowers demand fresh fuel with stabilizer to prevent clogs and carburetor issues. Yarbo's electric operation entirely bypasses fuel system concerns, offering a cleaner and simpler experience.

-

Clear Debris: After each use, clean out snow and ice to prevent rust buildup in conventional machines. Yarbo's IPX5 waterproof rating and extreme temperature resilience (-25°C to 45°C) with heating modules ensure it can withstand harsh elements, making post-use cleaning more straightforward while protecting internal components.

By following this checklist, you’ll drastically reduce mid-winter downtime and costly snowblowers maintenance or repair needs.

By following this checklist, you’ll drastically reduce mid-winter downtime and costly snowblowers maintenance or repair needs.

Common Snow Blowers Repair Issues and Fixes

Even with proper snowblower maintenance, snow blowers can run into trouble. Here are some of the most common repair issues:

-

Snow Blower Won’t Start & Engine Runs Rough: These issues are frequently caused by stale fuel, dirty carburetors, or faulty spark plugs in gas-powered units. Yarbo's electric design completely eliminates these common engine and fuel-related starting and running issues, simplifying reliability.

-

Clogged Discharge Chute: This can be prevented by using non-stick sprays or clearing wet snow in smaller passes. Yarbo's two-stage snow thrower is designed for efficient clearing of various snow types, including heavy, wet, and compacted snow, minimizing clogging.

-

Auger Not Turning: Broken shear pins are the typical culprit—keep extras handy. Yarbo’s robust auger system is built for endurance and includes safety mechanisms for gravel driveways to prevent damage from accidental gravel intake.

-

Drive System Problems: Worn-out belts may need replacement. Yarbo’s tracked drive system provides superior traction in snow and on slopes, offering a different, often more reliable, method of propulsion.

Knowing how to troubleshoot these issues helps you avoid unnecessary repair costs and downtime.

Pro Tips for Extending the Life of Your Snow Blower

-

Use Fuel Stabilizers: This is crucial for gas-powered machines to prevent clogs and keep gas fresh. Yarbo's electric operation means no fuel, no stabilizers, and no associated problems.

-

Store Properly: Keeping a traditional snow blower in a dry garage and covering it prevents rust. Yarbo boasts an IPX5 waterproof rating and extreme temperature resilience (-25°C to 45°C), with heating modules enabling operation as low as -40°C when powered on, making outdoor storage or prolonged exposure less of a concern.

-

Replace Worn Parts Quickly: Don’t wait for a small issue to turn into major repair. Yarbo’s modular design and fewer complex engine parts can lead to simpler maintenance over time.

-

Warm It Up: Letting the engine idle for a few minutes before tackling heavy snow is necessary for traditional snow blowers. Yarbo, being electric, does not require a warm-up period for engine performance, offering instant operation.

-

End-of-Season Care: Drain fuel, change oil, and lubricate before storage.

These steps keep your snow blower reliable for years instead of seasons.

When to Repair vs. Replace a Snow Blower

Sometimes, constant repairs cost more than investing in a new machine. Here’s a quick guide:

-

Repair if: Minor issues like belt replacements, spark plugs, or clogged chutes.

-

Replace if: Small parts like the shear pin can be replaced easily, for major engine failure, costly transmission issues, or the repair cost is more than half the price of a new snow blower.

If your snow blower is over 10 years old and breaks down often, it might be time to consider smarter alternatives.

Yarbo’s Smart Alternative: The Future of Snow Clearing

Traditional machines require regular snowblower maintenance, fuel, and repairs. For homeowners with large driveways and complex yards, this becomes time-consuming and costly.

Yarbo’s Smart Alternative: The Future of Snow Clearing

Traditional machines require regular snowblower maintenance, fuel, and repairs. For homeowners with large driveways and complex yards, this becomes time-consuming and costly.

-

Fully Robotic & Wireless

No manual pushing or pulling. Yarbo uses RTK-GPS, binocular cameras, IMU, and ultrasonic sensors for centimeter-level precision navigation and 360° obstacle detection, even in complex terrains like slopes up to 35° (70% grade). It automatically creates snow-clearing plans based on real-time weather updates and scheduling functions, allowing it to start cleaning immediately as snowfall begins to prevent accumulation, ensuring roads remain clear. No perimeter wires are needed, simplifying setup and operation.

-

Low Maintenance

Electric-powered, with fewer moving parts, and no gas or oil. This means no fuel stabilizers, no carburetor issues, and significantly reduced routine maintenance compared to gas models. Its IPX5 waterproof rating and extreme temperature resilience (-25°C to 45°C), with heating modules enabling operation as low as -40°C when powered on, ensure durability in harsh winter conditions. The wireless auto-charging system further simplifies its operation and enhances safety, avoiding direct contact and reducing the risk of electric shock.

-

Modular System

Switch between snow blowing, lawn mowing, and leaf blowing with one base unit. The Yarbo Core is the central hub, seamlessly integrating with various functional modules for year-round yard maintenance. This modular design not only reduces equipment purchase costs but also saves storage space, offering multiple uses with one machine, eliminating the need for multiple standalone tools.

-

Designed for Large & Complex Yards

Built for the kind of snow clearing ride-on blowers are used for, but without the manual effort. The Yarbo Snow Blower module is a two-stage snow thrower capable of clearing up to 12 inches of snowfall in a 21-24 inch wide path, throwing snow up to 40 feet away. Its unique Slope Pattern algorithm and snow track design optimize angles, reduce slippage, and enhance traction on steep driveways up to 36% (21°). It can also cope with various complex driveways and snow conditions, including gravel driveways with customizable height (maximum ground clearance of 2 inches) and a durable metal snow chute that can effectively withstand accidentally entering gravel. It efficiently handles fluffy dry snow, heavy wet snow, and compacted snow.

-

Strong Safety Assurance

Yarbo incorporates up to eight protection mechanisms, including automatic identification and avoidance of people, pets, and vehicles through app notifications. It is also equipped with an Emergency Stop Button, binocular rear camera, bumper, voice notification, side camera, warning light, and binocular front cameras, providing all-round safety during use, even in low-light environments.

-

Long-Term Savings and Value

While a premium investment, Yarbo can pay for itself in a few years by eliminating contractor fees and consolidating multiple seasonal tools into one system. It offers significant savings compared to purchasing separate commercial-grade equipment or hiring services for large properties.

By choosing Yarbo, you’re not just avoiding constant snow blowers repair—you’re upgrading to a smarter, all-season yard solution.

By choosing Yarbo, you’re not just avoiding constant snow blowers repair—you’re upgrading to a smarter, all-season yard solution.

Final Thoughts on Snow Blower Maintenance

A snow blower is an investment, and like any machine, it needs care to deliver peak performance all winter. With regular snowblower maintenance, quick fixes, and smart storage habits, you can avoid breakdowns and extend lifespan of a snow blower.

But if you’re tired of constant servicing and heavy labor, Yarbo offers a next-generation alternative—turning yard care into a fully automated, hassle-free experience.

FAQs

1. How is Yarbo better than a traditional snow blower?

Yarbo eliminates manual work, fuel maintenance, and repair hassles associated with traditional snow blowers by offering a fully robotic, low-maintenance, electric solution. Its modular design also provides year-round yard solutions, seamlessly transitioning between snow blowing, lawn mowing, and leaf blowing with a single base unit. It is designed for large and complex yards, offering superior safety, all-terrain adaptability, and convenience for homeowners.

2. How often should I perform snowblower maintenance?

Do a full inspection before the season, light checks every 5–6 uses, and a post-season tune-up.

Do a full inspection before the season, light checks every 5–6 uses, and a post-season tune-up.

3. What is the most common snow blowers repair issue?

Starting problems, usually from stale fuel or spark plug issues.

4. Can I use old gas in my snow blower?

No—old gas leads to carburetor clogs and poor performance. Always use fresh fuel with stabilizer.

No—old gas leads to carburetor clogs and poor performance. Always use fresh fuel with stabilizer.

5. How long do snow blowers last with proper maintenance?

On average, 10–15 years, depending on usage and upkeep.

6. How is Yarbo better than a traditional snow blower?

Yarbo eliminates manual work, fuel maintenance, and repair hassles while offering modular, year-round yard solutions.

-7.png?w=1001&h=621)

Private group · 33.0K members

Private group · 33.0K members